The Challenge: The Coolant Attack

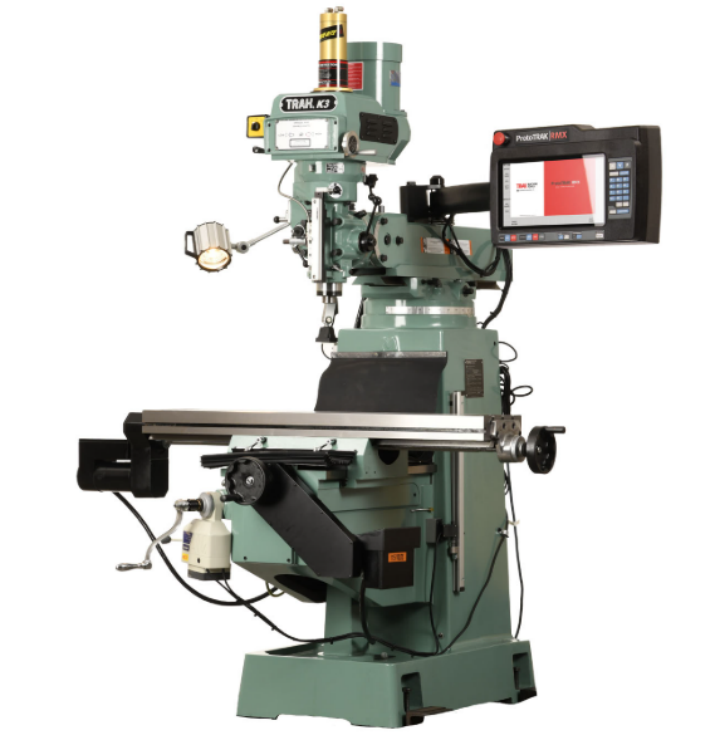

A CNC Machine Tool manufacturer found their painted badges were bubbling after 6 months. Aggressive Cutting Fluids were chemically attacking the paint.

The Solution: Surface Treatment Upgrade

Process Change: We switched to Hard Anodizing (Aluminum) and Chrome Plating (Zinc). Neither reacts with petroleum-based coolants.

Structure: Increased thickness to 3mm for a robust industrial feel.

The Result:

• Chemical Immunity: Zero degradation after 1 year of coolant exposure.

• Brand Value: The heavy badge matched the machine’s premium price.

#3D Metal Nameplates & label customization | Machinery Bonnet Nameplate

#WhatsApp: +8615867863626

Examples of different scenes

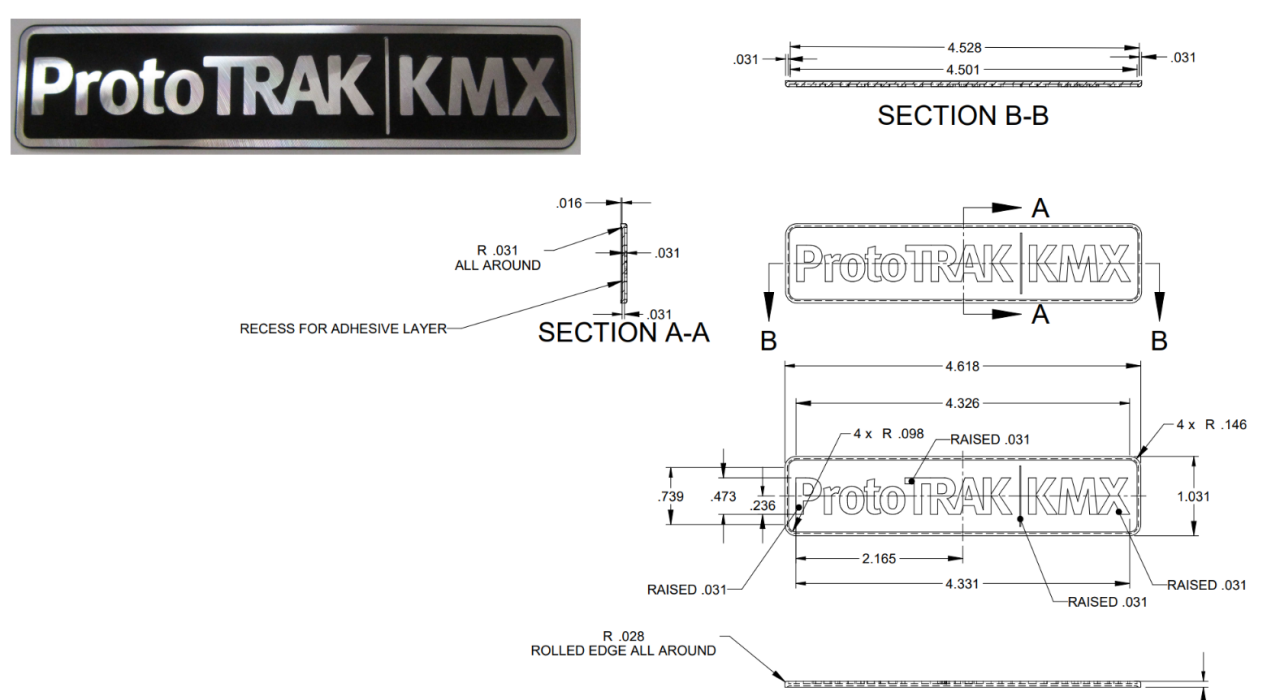

Products details

Technical Specifications

| Parameter | Specification & Details |

| Product Type | Machinery Bonnet Nameplate |

| Material | Extruded Aluminum 6063-T5 |

| Finish | 2000 PSI Pressure Wash Resistant |

| Impact | IK08 Rated |

certification

[Test Report] Snapshot of the quality specification

FAQ: Sourcing Strategy (Low MOQ)

Engineering Q&A: Installation

Q: Can the nameplate withstand 2000 PSI pressure washing?

A: Yes. We design our machine nameplates with specific mounting holes for Rivets. We optimize hole placement to prevent stress cracking during installation.

Leave a Reply