The Challenge: The “Banana Effect”

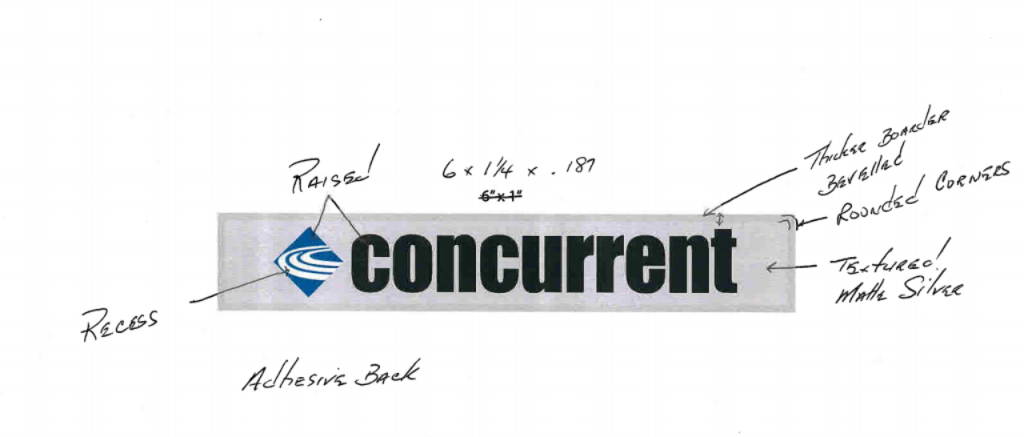

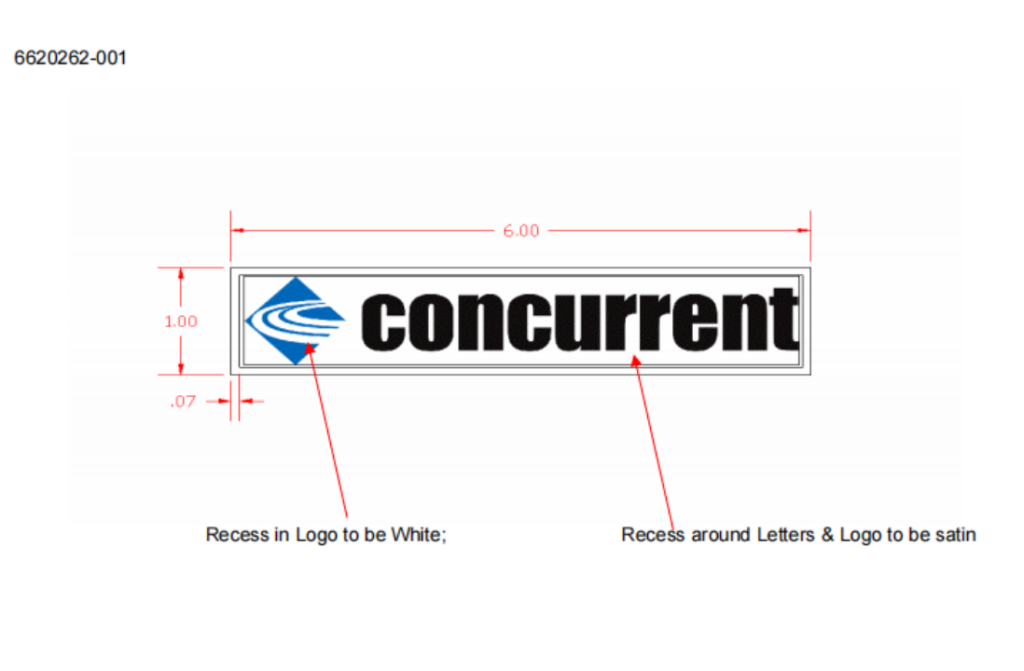

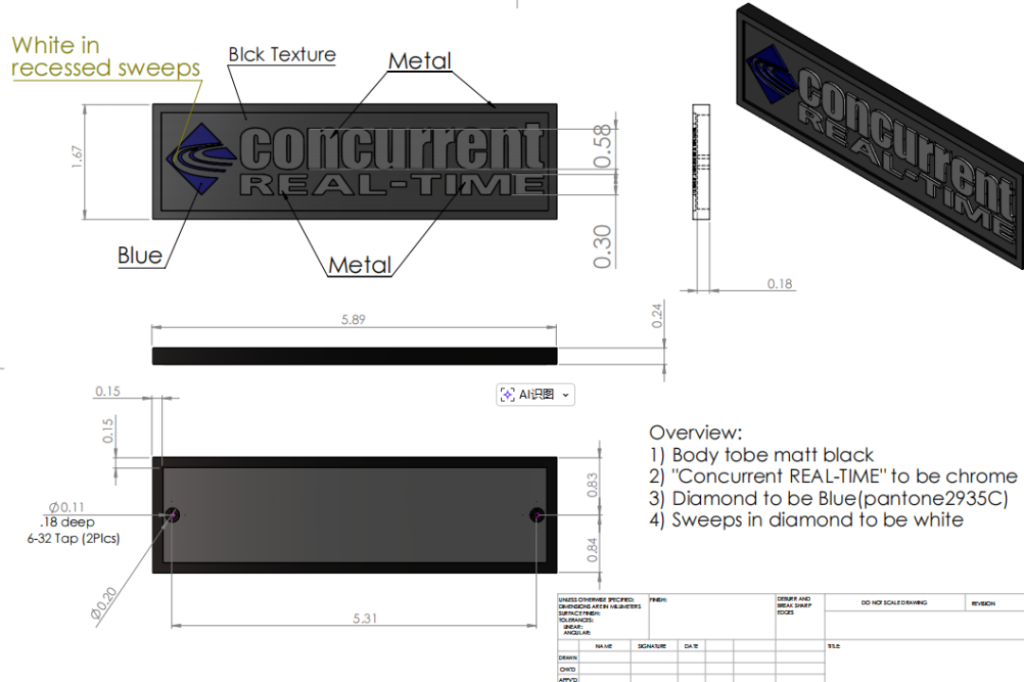

A leader in Real-Time Linux Computing required a 19-inch long equipment nameplate for a rackmount server bezel. Previous suppliers used standard die-casting, resulting in warping (the “Banana Effect”). Additionally, the heat from the server chassis caused standard adhesives to fail.

The Solution: Extrusion & Mechanical Locking

3D Custom Emblem re-engineered the part:

• Process Shift: We utilized Aluminum Extrusion. This produced a perfectly straight, rigid strip that maintains structural integrity over long spans.

• Mechanical Alignment: We engineered Dual Rear Studs into the profile. These fit into chassis holes with 0.1mm tolerance, securing the plate mechanically even if the server chassis reaches 80°C+.

The Result:

• Zero Distortion: The bezel sits perfectly flush with the server housing.

• Heat Immunity: Mechanical fixation eliminated adhesive failure risks.

https://concurrent-rt.com , The design inspiration comes from the content of the official website

#3D Metal Nameplates & label customization

#WhatsApp: +8615867863626

Examples of different scenes

Products details

Technical Specifications

| Parameter | Specification & Details |

| Product Type | Metal Nameplates System Emblem |

| Material | Aluminum 1050 (99.5% Purity) |

| Process | Diamond Cut (CD Pattern) + Anodizing |

| Vibration | SAE J1455: Compliant |

| Adhesive | 3M 468MP High-Performance Transfer Tape |

certification

FAQ: Sourcing Strategy (Low MOQ)

Engineering Q&A: Precision Fit

Q: How do you ensure fit on long server bezels?

A: For long components like server bezels, die-casting can cause warping. We utilize Aluminum Extrusion to ensure perfect straightness. We also incorporate Rear Studs for mechanical alignment, ensuring a tolerance of +/- 0.1mm.

Leave a Reply