The Challenge: The Sweat Test

A designer handbag brand faced tarnishing issues. Gold-plated tags were fading after contact with customers’ skin.

The Solution: Advanced Plating

Barrier Layer: Added a thicker Acid Copper layer to seal the base metal.

Top Coat: Applied electrolytic Anti-Tarnish Clear Coat (E-Coat).

Validation: Passed ISO 105-E04 Artificial Perspiration Test.

The Result:

• Durability: 2-year warranty against tarnishing.

• Safety: Certified 100% Nickel-Free.

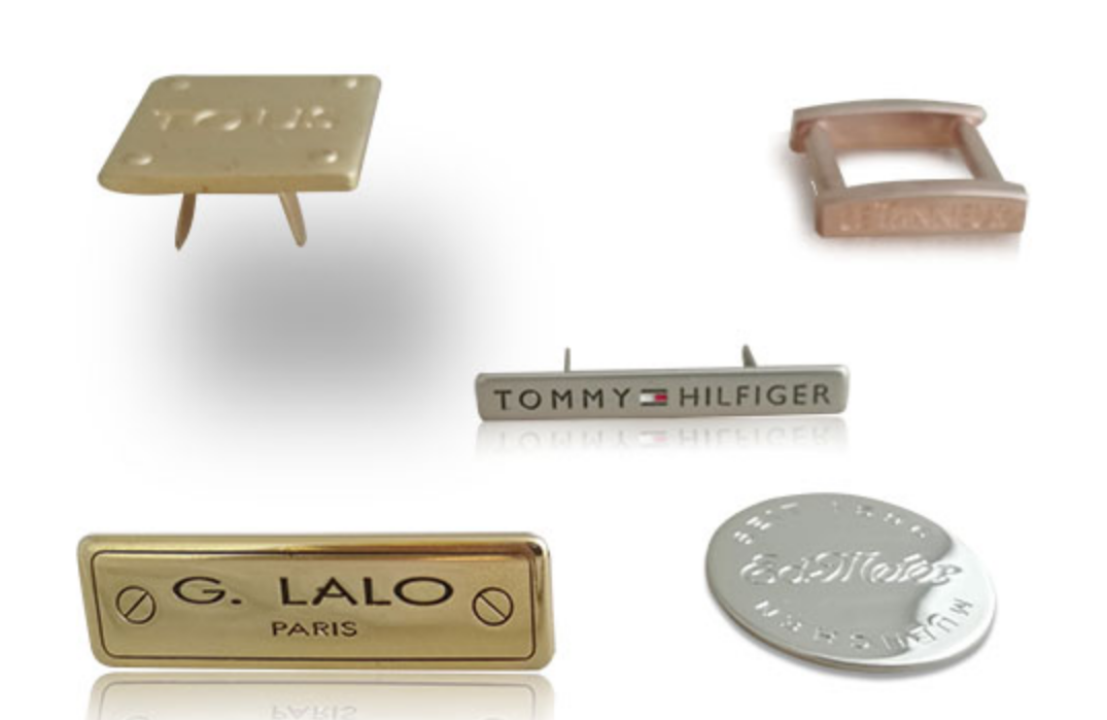

#3D Metal Nameplates & label customization | Handbag Hangtag / Logo Charm

#WhatsApp: +8615867863626

Examples of different scenes

Products details

Technical Specifications

| Parameter | Specification & Details |

| Product Type | Handbag Hangtag / Logo Charm |

| Material | Zamak 3 Zinc Alloy (High Density 6.6 g/cm³) |

| Plating | Copper + Nickel + Chrome (Multi-layer) |

| Pull Force | > 10kgf (Secure Attachment) |

| Resistance | Perfume & Hand Oil Resistant |

certification

[Test Report] Snapshot of the quality specification

FAQ: Sourcing Strategy (Low MOQ)

Engineering Q&A: Plating Quality

Q: How do you prevent “Dust Points”?

A: We utilize Rack Plating and rigorous tank filtration. This ensures a mirror-smooth finish with absolutely no “star-dusting” or roughness, critical for luxury goods.

Leave a Reply