The Challenge: The 0.05mm Gap

A rugged laptop manufacturer faced quality issues where logo plates were varying in size, leaving ugly gaps in the recessed housing where dust accumulated.

The Solution: Precision Tooling

Fine Blanking: We utilized high-precision Fine Blanking dies to reduce edge burr.

100% Gauging: We built a custom “Go/No-Go” gauge fixture. Every batch is sampled to ensure dimensions fall within +/- 0.05mm.

The Result:

• Flush Fit: A seamless, high-tech look with no gaps.

• Reliability: No dust ingress points.

#3D Metal Nameplates & label customization | Laptop Lid Recessed Logo

#WhatsApp: +8615867863626

Examples of different scenes

Products details

Technical Specifications

| Parameter | Specification & Details |

| Product Type | Laptop Lid Recessed Logo |

| Material | Aluminum 5052-H32 |

| Finish | Hard Anodized (15-20 Microns) |

| Abrasion | RCA Wear Test: > 100 Cycles |

| Hardness | Pencil Hardness 3H+ |

certification

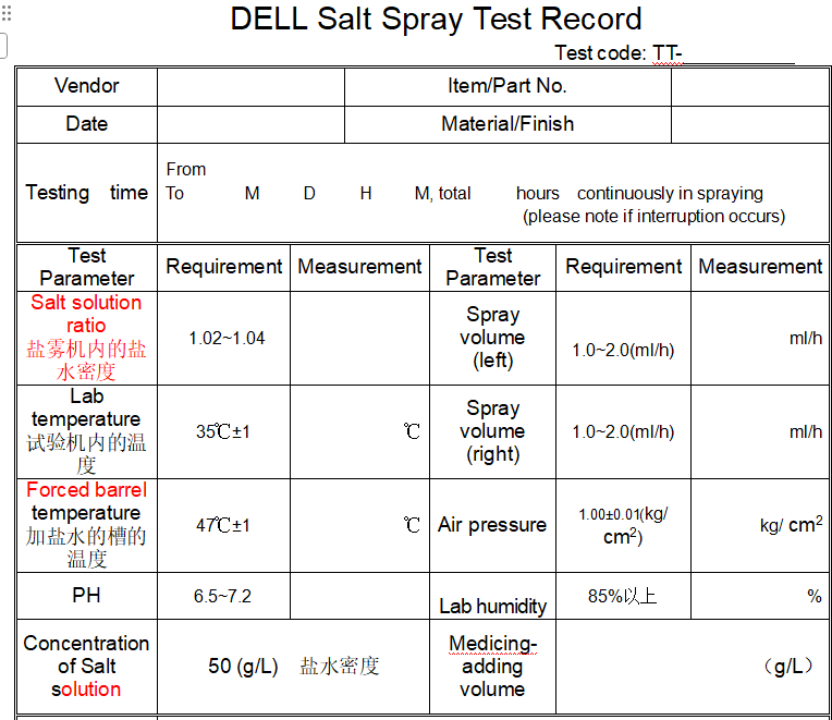

[Test Report] Snapshot of the quality specification

FAQ: Sourcing Strategy (Low MOQ)

Engineering Q&A: Abrasion Resistance

Q: How to ensure the logo doesn’t scratch off?

A: We validate finishes using the RCA Abrasion Wear Test. Our logos withstand 100+ cycles of friction and “Artificial Sweat” tests.

Leave a Reply