The Challenge: The “Yellow Badge” Failure

A manufacturer of portable solar generators faced a brand crisis. Their previous clear epoxy doming badges were turning yellow and cracking after just 6 months outdoors.

The Solution: Material Upgrade

3D Custom Emblem proposed a two-fold change:

• Material: We switched to Die-Cast Zinc Alloy with Baked Enamel paint, which is impervious to UV radiation.

• Adhesive: We utilized 3M VHB 5952 Tape. This viscoelastic tape expands and contracts with the plastic casing during day/night thermal cycling, maintaining a waterproof seal.

The Result:

• 10-Year UV Stability: No fading or yellowing.

• Adhesion: Passed 500-hour Thermal Shock Test (-40°C to +85°C).

#3D Metal Nameplates & label customization | BBQ Grill Lid Emblem

#WhatsApp: +8615867863626

Examples of different scenes

Products details

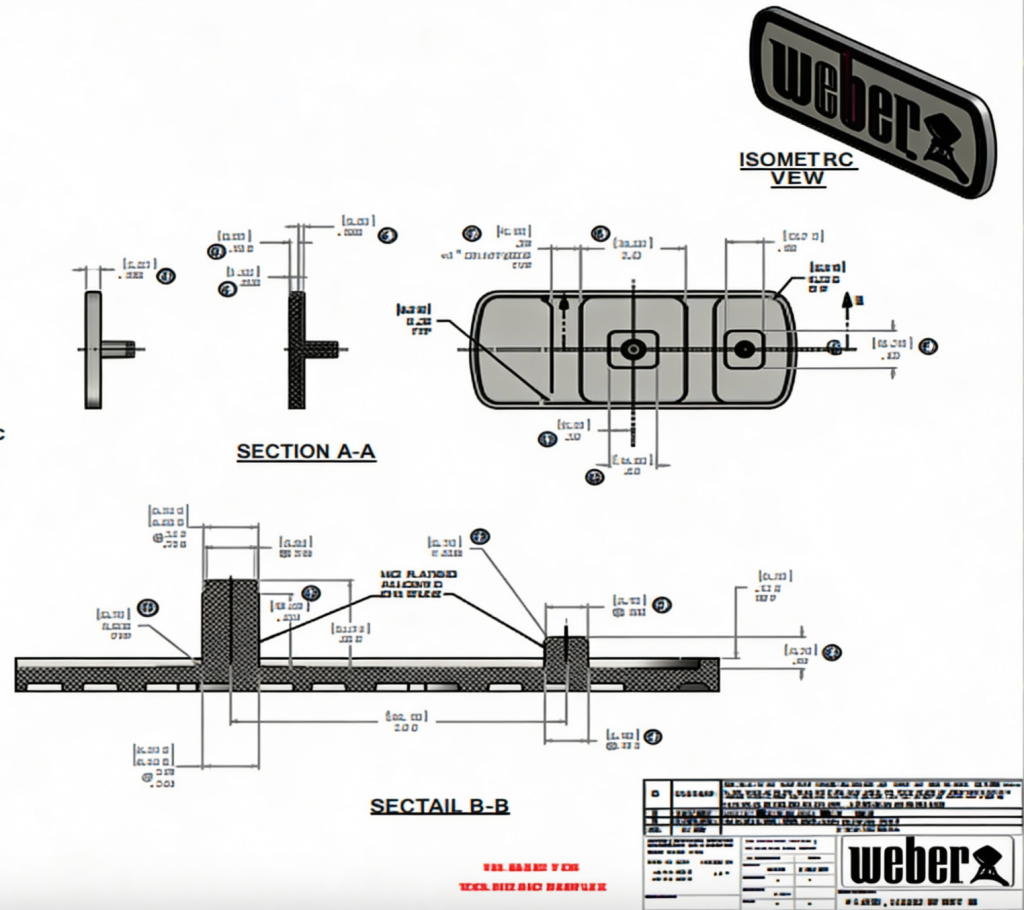

Technical Specifications

| Parameter | Specification & Details |

| Product Type | BBQ Grill Lid Emblem |

| Material | Die-Cast Aluminum Alloy (ADC12) |

| Condition | Extreme Heat: -20°C to 315°C (600°F) |

| Salt Spray | ASTM B117: Passed 200 Hours |

| Life Span | 10+ Years |

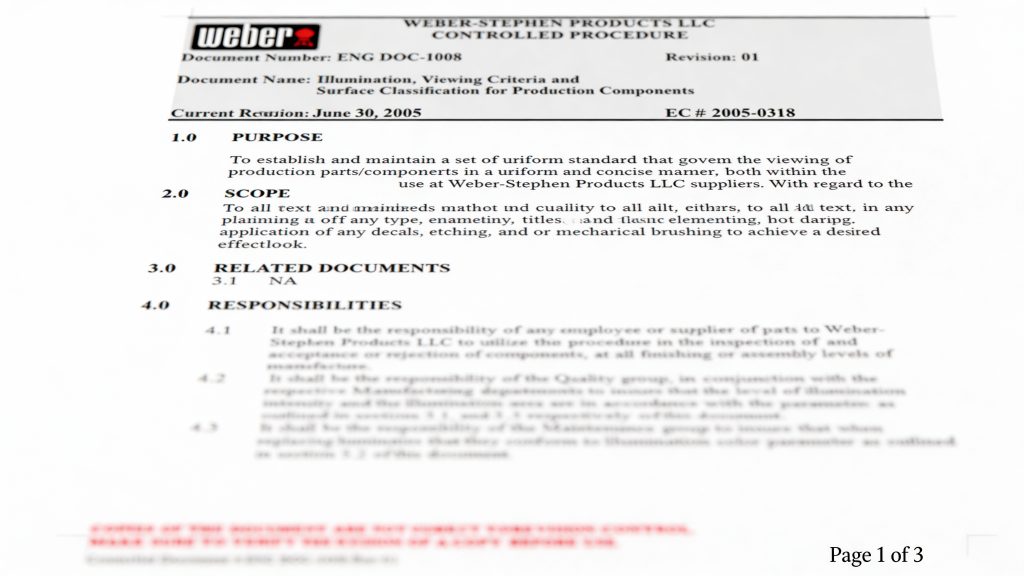

certification

[Test Report] Snapshot of the quality specification

FAQ: Sourcing Strategy (Low MOQ)

Engineering Q&A: The “Yellowing” Problem

Q: Will the logo fade or peel on solar generators exposed to 50°C desert heat?

A: Standard Epoxy (Doming) labels will yellow and crack under UV. We strictly refuse to use standard epoxy for solar applications. Instead, we use Zinc Alloy or Aluminum with Baked Enamel, paired with 3M VHB 5952 tape to withstand thermal expansion.

Leave a Reply